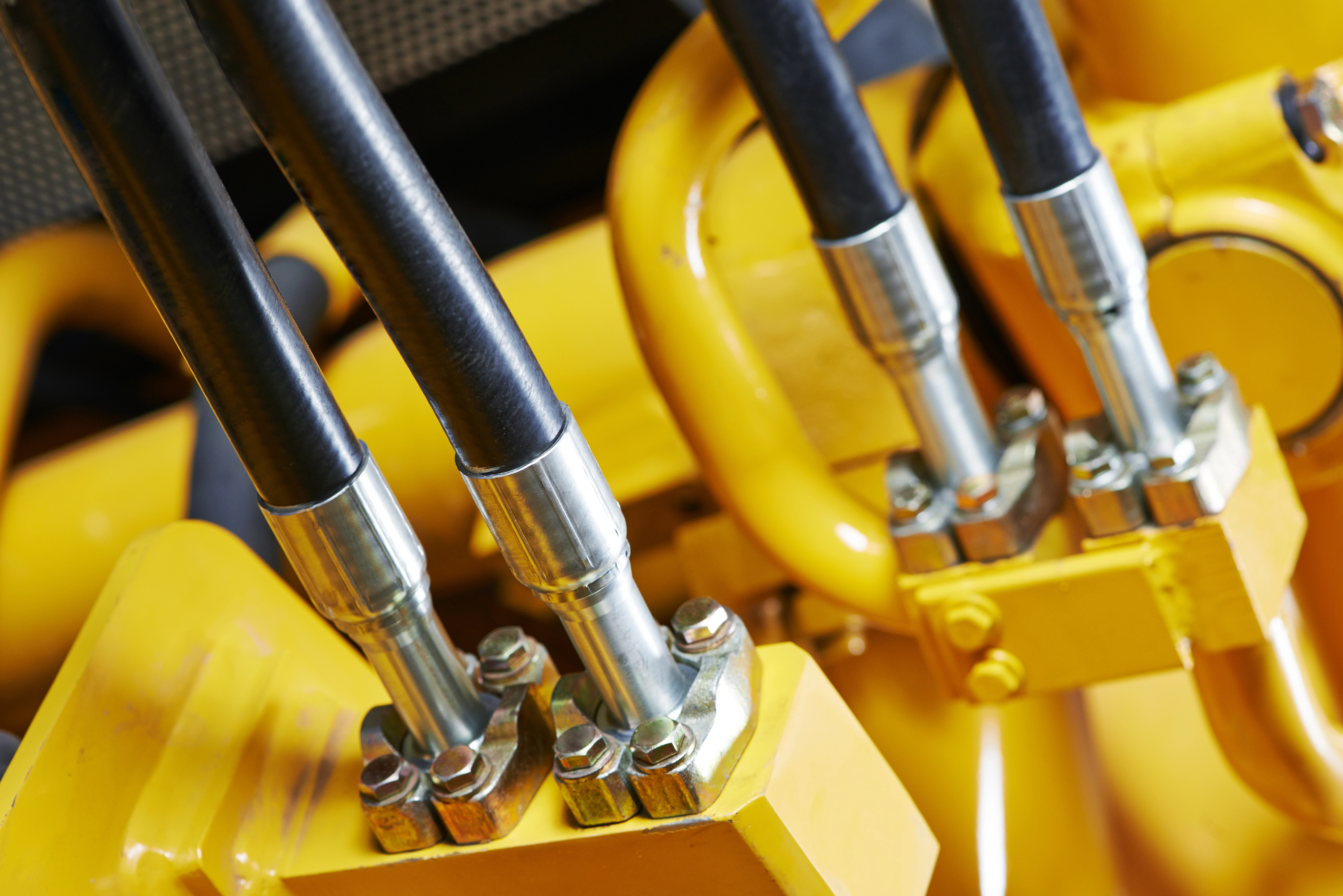

An Introduction to Selecting Brass or Stainless Steel in High-Pressure Hydraulics

In the complex world of hydraulic systems, the choice of material is crucial, especially when dealing with high-pressure environments. Two popular options are brass and stainless steel. Each has its own set of advantages and limitations, making them suitable for different applications. Understanding how they perform under extreme pressure can help engineers and technicians make informed decisions that ensure system reliability and safety.

The Critical Role of Materials in Hydraulics

Material selection isn't just about compatibility with hydraulic fluids or cost; it's about ensuring the system can endure the intense forces at play. In high-pressure scenarios, materials must not only withstand the immediate stress but also resist wear, fatigue, and corrosion over time. The right material can mean the difference between a long-lasting, efficient system and one that fails prematurely, potentially leading to costly downtime or safety hazards.

Brass in High-Pressure Applications: Pros and Limitations

Brass has long been used in hydraulic systems due to its good corrosion resistance and ease of machining. It’s commonly found in low to medium-pressure systems where the risk of deformation is minimal. However, under high pressure, brass begins to show its limitations. Its tensile strength is lower compared to stainless steel, which makes it more prone to deformation, cracking, or failure when subjected to extreme conditions.

- Brass is typically used in low to moderate pressure hydraulic systems.

- Standard brass components usually operate up to around 1,000–3,000 PSI.

- Some specialized brass alloys may handle slightly higher pressures, but they’re rarely used in the most demanding applications.

Stainless Steel: The Preferred Choice for High-Pressure?

Stainless steel is often the go-to material for high-pressure hydraulic systems. Known for its exceptional strength, durability, and resistance to both corrosion and high temperatures, it offers a reliable solution for challenging environments. Whether in industrial machinery, marine equipment, or aerospace systems, stainless steel consistently performs under extreme conditions without compromising structural integrity.

- Stainless steel is ideal for medium to high-pressure hydraulic systems.

- Standard stainless steel components can handle pressures ranging from 5,000 to 10,000 PSI or more.

- High-grade stainless steels like 316 or 17-4 PH are often used in ultra-high-pressure applications.

Comparative Analysis: Brass vs. Stainless Steel under Pressure

When comparing brass and stainless steel in high-pressure situations, several factors stand out:

- Tensile Strength: Stainless steel has significantly higher tensile strength, making it better suited for high-pressure environments.

- Corrosion Resistance: While both materials resist corrosion, stainless steel performs better in harsher chemical environments.

- Longevity: Stainless steel tends to last longer under continuous high-pressure use, reducing the need for frequent replacements.

Real-World Applications and Case Studies

In industries such as aerospace, oil and gas, and heavy manufacturing, stainless steel is the preferred material for high-pressure hydraulic systems. For example, deep-sea exploration equipment and large-scale industrial presses rely on stainless steel for its strength and reliability. On the other hand, brass remains a practical option in less demanding settings, such as residential plumbing or light-duty machinery, where the pressure levels are not extreme.

The Cost-Benefit Equation

While brass is generally cheaper upfront, its lower durability can lead to higher maintenance and replacement costs over time. In contrast, stainless steel may have a higher initial price tag, but its longevity and performance often make it more cost-effective in the long run, especially in critical high-pressure systems where failure is not an option.

Conclusion: Making the Right Choice

Choosing between brass and stainless steel depends on the specific requirements of the hydraulic system. If the application involves high pressure, corrosion, or extreme temperatures, stainless steel is the safer and more durable choice. However, for moderate-pressure systems where cost is a primary concern, brass can still be a viable option.

Ensuring Optimal Performance

Regardless of the material chosen, regular maintenance, proper installation, and adherence to manufacturer guidelines are essential for optimal performance. Understanding the operational environment and selecting the right material will help maximize the lifespan and efficiency of any hydraulic system.

Frequently Asked Questions

How does the cost of brass compare to stainless steel in hydraulic systems?

Answer: Brass is typically less expensive upfront than stainless steel. However, in high-pressure systems, stainless steel’s durability and lower long-term maintenance costs often make it more cost-effective over time.

Is brass or stainless steel better for high-temperature applications in hydraulic systems?

Answer: Stainless steel is the better choice for high-temperature environments. It retains its strength and structural integrity at elevated temperatures, unlike brass, which can soften and deform under heat.

Acoustic Guitar Tuner,Cheap Guitar Tuner,Guitar Tuner Metronome,Rechargeable Guitar Tuner

GUANGZHOU GIDOO MUSICAL INSTRUMENTS CO.,LTD , https://www.kaysenguitar.com