Talking Fusion Production with visitors

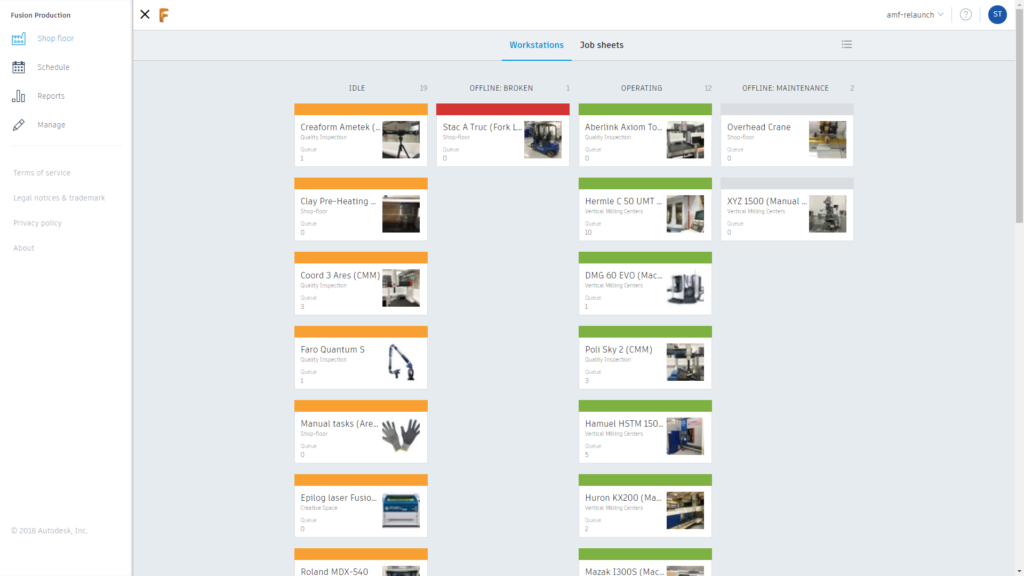

A comprehensive view of the workstations at the AMF

Autodesk CEO Andrew Anagnost sees Fusion Production in action

One of the key features that resonated with the customers I spoke to was the ability to capture and feed back data throughout the production cycle. This has been a challenge for many before, as they lacked a single tool to manage the entire process. With Fusion Production, they can now evaluate their current performance, spot bottlenecks, and make data-driven decisions to boost throughput and efficiency. The manufacturing industry is undergoing a huge transformation, and we're excited to be at the forefront, providing tools that help our customers embrace smart manufacturing. There’s still a lot more on the horizon, and I’m looking forward to seeing how Fusion Production continues to evolve and support our users. If you want to learn more about Fusion Production or explore the Advanced Manufacturing Facility, check out the official resources to dive deeper.The fixing angle of a Tower Crane refers to the angle at which the crane is secured to its base or foundation. It is important to ensure that the crane is properly fixed at the correct angle to ensure stability and safety during operation.

The fixing angle of a tower crane is typically determined by the manufacturer and specified in the crane's operating manual. It is usually set at a specific angle to provide optimal stability and load capacity for the crane.

The fixing angle can be adjusted during the initial installation of the crane to ensure it is level and properly aligned. This is typically done using leveling jacks or other adjustable components at the base of the crane.

It is important to follow the manufacturer's guidelines and recommendations when setting the fixing angle of a tower crane to ensure safe and efficient operation. Improper fixing angle can lead to instability, tipping, or other safety hazards.

Tower crane fixing angle is connected between tower body and concrete foundation. Usually, the model of fixing angle is based on the tower crane Mast Section, such as 1.2m s24 mast section, 1.6m L46a1 mast section, 2.0m l68b2 mast section.

Fixing angle is used for connecting of tower crane foundation and tower crane body. Usually the fixing angle is fixed inside the concrete foundation. However, there is one type of tower crane fixing angle which is reusable type. The reusable type fixing angle could be removed from the foundation after tower crane disassembly.

Fixed Leg Fixing Angle,Reusable Fixing Angle,Tower Crane Fixing Angle,Tower Crane Reusable Fixing Angle,Foundation Anchor Fixing Angle

SHEN YANG BAOQUAN , https://www.bq-cranes.com