Robotic Laser Metrology Transforms Inspection Processes Across Industries

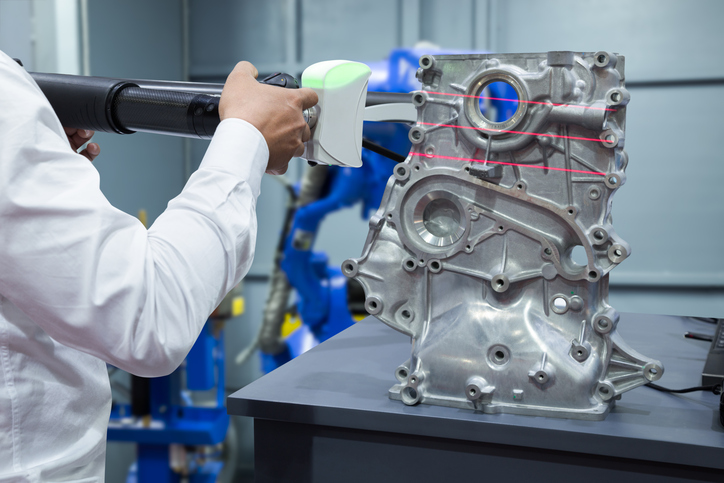

Robotic laser metrology represents a groundbreaking leap forward in the field of manufacturing inspection. This innovative technology combines the precision of laser radar systems with the flexibility of a six-axis robotic arm, allowing for unparalleled speed, accuracy, and adaptability in part inspection. By enabling real-time data capture and analysis, robotic laser metrology has become an indispensable tool for industries striving for excellence in quality control.

Its applications span across multiple sectors, including automotive, aerospace, defense, and even space exploration. Whether you're inspecting intricate aircraft components or ensuring the integrity of composite materials, robotic laser metrology offers unmatched versatility and precision. The technology excels in scenarios where access is limited or manual inspections prove time-consuming and error-prone.

The Advantages of Robotic Laser Metrology

One of the standout advantages of robotic laser metrology is its seamless integration into existing production lines. Unlike traditional inspection methods, which often act as bottlenecks, this technology operates in sync with the pace of manufacturing. This results in improved throughput and reduced downtime, ultimately boosting overall productivity.

Laser radar technology ensures high accuracy by capturing detailed measurements of various materials. These measurements can then be analyzed to identify trends, optimize processes, and maintain strict quality standards. Additionally, robotic laser metrology requires minimal maintenance, making it a cost-effective solution for businesses looking to enhance their inspection capabilities without breaking the bank.

Diverse Applications Across Industries

Although relatively new on the scene, robotic laser metrology has already demonstrated its value in numerous contexts. Here are some of the most common use cases:

- Inspecting critical aircraft components for safety compliance

- Performing inline and next-to-the-line inspections in automotive plants

- Assessing the quality of composite materials used in advanced manufacturing

- Single-run inspection of large parabolic antennas

- Measuring heated surfaces near industrial equipment like blast furnaces

- Optimizing part geometry to improve product design and performance

Regardless of your industry, robotic laser metrology offers significant benefits over conventional inspection techniques. It not only enhances accuracy but also streamlines operations, providing manufacturers with a competitive edge in today's fast-paced market.

To delve deeper into how Genesis Systems Group leverages robotic metrology solutions for the automotive, aerospace, and broader manufacturing sectors, feel free to explore our resources further. Our commitment to innovation ensures that we stay ahead of the curve when it comes to delivering cutting-edge tools that empower businesses worldwide.

As industries continue to evolve, embracing technologies like robotic laser metrology becomes crucial for staying relevant and competitive. By adopting these advancements, companies can achieve higher levels of efficiency, reliability, and customer satisfaction—all while reducing costs associated with inefficient inspection practices.

Posted in Technology and InnovationHot Rolled Strip Steel Coil Modal

Hot Rolled Strip Steel Coil Modal,Steel coil intelligent sorting machine,Big Data optimization bale,All-round intelligent bundling solution

YANBIAN LONGCHUAN PACKING MACHINERY CO., LTD , https://www.yblcmachinery.com