Robotic Laser Metrology: A New Era in Precision Inspections

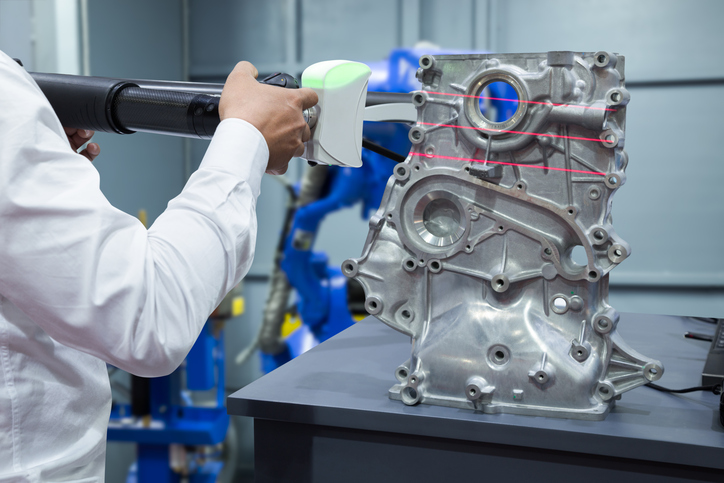

Robotic laser metrology represents a groundbreaking advancement in the field of industrial inspection. This technology combines the precision of laser radar systems with the versatility of robotic arms, enabling faster, more accurate, and more efficient part inspections than ever before. The integration of robotics into metrology has opened up new possibilities across multiple industries, including automotive, aerospace, defense, and manufacturing.

One of the key advantages of robotic laser metrology is its ability to handle complex, hard-to-reach areas that were previously challenging or impossible to inspect manually. Whether it's measuring intricate components within an aircraft engine or assessing the surface quality of large-scale structures like parabolic antennas, this technology provides unparalleled access and accuracy. Furthermore, its application extends beyond static inspections; it can even measure heated surfaces near blast furnaces—conditions that would otherwise compromise human safety and equipment durability.

Unparalleled Benefits of Robotic Laser Metrology

What sets robotic laser metrology apart from conventional methods? Firstly, its adaptability makes it ideal for both standalone operations and seamless integration into existing production lines. By performing inspections in real time alongside manufacturing processes, companies can significantly reduce downtime and improve overall throughput without sacrificing quality standards. Additionally, laser radar systems offer superior measurement accuracy while handling diverse materials such as composites, metals, plastics, and ceramics—all essential elements in modern engineering projects.

Another major advantage lies in cost-efficiency. Since these systems require minimal upkeep compared to other advanced technologies, businesses can enjoy long-term savings on maintenance expenses. Moreover, their modular design facilitates quick reconfiguration when transitioning between tasks or adapting to changing project requirements, ensuring maximum flexibility at every stage of development.

Applications Spanning Multiple Sectors

Despite being relatively young compared to traditional inspection tools, robotic laser metrology has already made significant strides across various sectors. Some standout examples include:

- Inspecting critical components of commercial airplanes during assembly phases.

- Conducting inline inspections on automobile parts prior to final assembly.

- Assessing composite materials used in wind turbine blades or spacecraft construction.

- Evaluating parabolic reflectors for satellite communication dishes after fabrication.

- Monitoring thermal expansion effects on industrial machinery operating under extreme heat conditions.

These applications demonstrate how versatile this technology truly is. From ensuring compliance with stringent regulatory guidelines to enhancing product reliability through enhanced geometric optimization, robotic laser metrology plays a crucial role in driving innovation throughout today’s competitive market landscape.

In conclusion, adopting robotic laser metrology isn't just about staying ahead of competitors—it's about embracing change proactively so you can deliver better products faster while maintaining high levels of customer satisfaction. If your organization faces challenges related to slow inspection cycles or unreliable data collection methods, consider exploring how Genesis Systems Group's cutting-edge solutions could transform your workflow today!

Posted in Technology & Innovation

Automatic Strapping Machine For Galvanized Pipe

Automatic Strapping Machine For Galvanized Pipe,Versatile Pipe Bundler for Various Diameters,Quick-Cycle Auto Strapping for Fast Packaging,Compact Auto Bundling for Tight Storage

YANBIAN LONGCHUAN PACKING MACHINERY CO., LTD , https://www.yblcmachinery.com