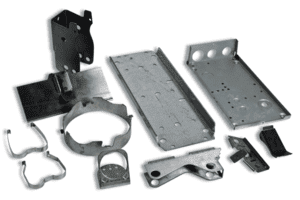

ESI understands the demands of our clients' industries, and we are committed to helping them save money on their Stamped Metal Parts without compromising the quality of their products. We've been in business for over three decades, consistently providing innovative engineering solutions and manufacturing services, including leveraging the latest automated systems. Our expertise primarily stems from delivering safety-critical components to the automotive sector—an industry that demands precision, speed, and efficiency.

Here are three key areas you can focus on to optimize the cost of your Stamped Metal Parts.

Materials

The cost of metal stamping can fluctuate greatly depending on subtle variations in the properties of the raw materials used. Harder materials, for instance, require more effort and time to stamp, making them more expensive. However, you can save both time and money by opting for softer or less abrasive materials that don’t sacrifice the required quality standards of your part. Some materials might have significant price differences but offer comparable properties.

Switching to a different material can lower costs while maintaining the quality and structural integrity of the part, depending on the current component specifications and market prices. For example, if you originally chose a specific material for a component due to its unique characteristics, but the minimum standards for the part have since changed, you can safely transition to less expensive alternatives.

Tooling Requirements

When collaborating with a metal stamping company, evaluating the tooling requirements of your part is essential. Even a small adjustment in tooling can significantly impact costs and production timelines. Minimizing the frequency of repairs and retooling is critical, as these can result in unnecessary expenses and downtime. For instance, creating square holes in a component requires more machining and tooling compared to round ones. Therefore, reviewing your tooling needs can help identify modifications that reduce complexity while preserving functionality.

Additionally, identifying features that contribute to downtime and simplifying your component design can prevent unnecessary changes in tooling requirements. Excessive abrasive wear on a metal stamping die often stems from complex features or notches. Without proper maintenance, this can lead to fatigue cracking. If such features are necessary, a more rigorous maintenance schedule is advisable.

Production Volume

Increased demand for your components usually necessitates larger production volumes. Higher order quantities enable the optimization of product designs to enhance manufacturability and streamline production timelines. For those utilizing prototype designs, now is the time to explore opportunities for adjustments that maintain the required functionality of the component while reducing costs.

Raw material and finishing costs can vary substantially based on the volume purchased. Placing blanket orders for your parts over a specified time frame with smaller weekly or monthly releases is often advantageous.

Reviewing complex features for revisions improves the quality control of your components and allows for longer intervals between scheduled tooling maintenance. Understanding the Estimated Annual Usage (EAU) of your parts is equally important. Depending on the volume and frequency of your production runs, various options for tool material and coatings may be available to save money while achieving the desired outcomes, including multi-cavity tooling.

Modifications to the original design material might also be feasible. Decreasing the thickness of your material or switching to a more malleable metal extends die life and can reduce material costs. Occasionally, the volume surpasses expectations, requiring the metal stamping provider to create additional tools to handle the increased output. Sharing product volume projections upfront is vital, as it helps determine whether multiple dies will be necessary to achieve the desired production levels.

Quality and Cost-Effective Metal Stamping Services

You can significantly cut down on metal stamping costs by examining your materials, tooling requirements, and production volumes. ESI is an industry leader in engineering services and manufacturing solutions, and we’re here to assist you in achieving that goal.

We work closely with clients throughout the entire process to ensure a cost-efficient metal stamping operation that still meets your needs and adheres to industry standards. Contact the ESI team today and request a quote.

As someone who has worked with metal stamping for years, I’ve seen firsthand how small changes in these areas can add up to significant savings. For example, one client was able to cut their costs by nearly 20% simply by switching to a slightly less expensive material without losing any functional performance. Another realized substantial savings by tweaking their tooling design to eliminate unnecessary complexity.

Of course, every project is unique, so it’s always best to consult with experts like ESI early in the process. They can provide tailored recommendations based on your specific needs and budget constraints. Whether you’re just starting out or looking to scale up, optimizing these factors can make a big difference in your bottom line.

Let me know if you’d like to hear more about some real-world examples where companies have achieved impressive results through smarter metal stamping strategies. There’s so much potential for improvement, and I’d be happy to share insights from my experience!

Vacuum Calibration Tank,Extrusion Calibration Tank,Pipe Calibration Tank

Zhangjiagang Polestar Machinery Co.,Ltd , https://www.polestarpm.com

Comments are closed