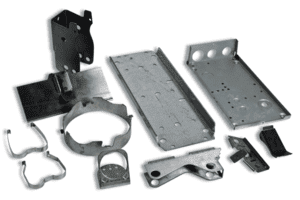

At ESI, we understand the pressures faced by our clients in various industries, and our mission is to assist them in cutting costs on stamped metal parts without compromising product quality. With over three decades of experience under our belt, we consistently offer innovative engineering solutions and advanced manufacturing services, utilizing state-of-the-art automated systems. Our expertise primarily stems from supplying safety-critical parts to the automotive sector, which demands excellence in quality, speed, and efficiency.

There are several key areas you can examine and optimize to reduce the expenses associated with stamped metal parts. Let's dive into three critical aspects: materials, tooling requirements, and production volume.

Materials

The cost of metal stamping can fluctuate greatly depending on subtle variations in the properties of raw materials. For example, harder metals demand more effort and time to stamp, making them pricier. However, by opting for softer or less abrasive materials that meet your part's quality standards, you can save both time and money. Certain materials exhibit significant price differences yet provide comparable properties.

Switching to a different material could save you money while maintaining the quality and structural requirements of the part, contingent upon the current component specifications and market pricing. For instance, if a specific material was chosen initially for its unique characteristics, but the minimum standards for the part have since evolved, it might be feasible to transition to a less costly alternative.

Tooling Requirements

When collaborating with a metal stamping company, assessing the tooling requirements for your part is essential. Even minor adjustments in tooling can drastically affect costs and production timelines. Minimizing repair and retooling instances is vital, as these can incur unnecessary expenses and disrupt production schedules. For instance, creating square holes in a component involves more machining and tooling compared to round ones. Therefore, evaluating your tooling needs can reveal modifications that reduce complexity while preserving functionality.

Determining which features contribute to downtime and revising your design to simplify components can prevent unnecessary changes in tooling requirements. Excessive abrasive wear on a metal stamping die usually arises from intricate features or notches. This can lead to fatigue cracking if proper maintenance isn't carried out. If such features are necessary, a more rigorous maintenance plan is advisable.

Production Volume

Increased demand for your components often necessitates larger production volumes. Higher volumes enable streamlining of product designs to enhance manufacturability and production timelines. For those utilizing prototype designs, now is the time to identify opportunities for modifications that maintain the required functionality while reducing costs.

Raw material and finishing costs vary considerably based on the volume purchased. Bulk orders for parts over a set timeframe, with smaller weekly or monthly releases, are frequently advantageous.

Reviewing complex features for revisions improves the quality control of your components and allows for extended periods between scheduled tooling maintenance. Understanding the Estimated Annual Usage (EAU) of your parts is equally important. Depending on production run volume and frequency, different tool material and coating options may be available to save money while achieving desired outcomes, including multi-cavity tooling.

Adjusting the material from your original design might also be viable. Thinning the material or switching to a more ductile metal extends die lifespan and reduces material costs.

Sometimes, demand exceeds expectations, requiring the creation of additional tools to handle higher volumes. Informing your metal stamping provider about expected product volumes upfront is crucial as it aids in determining whether multiple dies will be needed to meet output goals.

Quality and Cost-Effective Metal Stamping Services

You can significantly lower your metal stamping costs by scrutinizing materials, tooling requirements, and production volumes. ESI stands as a leading provider of engineering services and manufacturing solutions, ready to assist you in achieving this goal.

We support clients throughout the entire process to ensure a cost-efficient metal stamping procedure that still meets their needs and industry standards. Reach out to the ESI team today and request a quote.

Plastic extruder,Plastic extruder machine,Plastic sheet extruder machine,Extruder plastic,Plastic board extruder,Plastic pipe extrusion

Zhangjiagang Polestar Machinery Co.,Ltd , https://www.polestarpm.com

Comments are closed