UT Drone Inspections at a Cement Plant

Key Benefits in a Nutshell

|

Access |

Speed Using the Elios 3 UT significantly speeds up inspections, allowing multiple large assets to be checked in just one day. |

|

Safety By using a UT drone for inspections, the need for scaffolding and rope access is eliminated, greatly reducing risks to workers. |

Data Quality The Elios 3 captures ultrasonic thickness measurements inside structures to meet industrial inspection standards, enabling better digital asset management. |

Why UT Drone Inspections Matter in Industry

The Elios 3 is a specialized drone designed to navigate complex and confined spaces without requiring human entry, significantly reducing staff risk. It can reach the interiors of stacks or silos to gather vital data that helps assess the condition of equipment and identify maintenance needs early. InspecDrone, a German inspection company, tested the new UT payload for the Elios 3. They visited a cement plant to inspect various assets and demonstrate how the drone could streamline and enhance the inspection process.How the Elios 3 UT Drone Inspects Key Assets

1. Flue Duct

One of the first assets inspected was a flue duct. The duct starts as rectangular but transitions into a more rounded shape. Part of it had been replaced, and the client wanted to assess the degradation of the fixed steel. This duct carries hot, corrosive air and dust up to 300°C, making regular inspection crucial. Traditional methods required extensive preparation, including setting up ropes and safety protocols, which could take a full day. A team of three people was typically involved, with one climbing, another monitoring, and the third assisting. With the Elios 3, the process became much simpler. The drone entered the duct and flew through the target area under the control of a single pilot. The entire inspection took less than two hours. For this type of inspection, it's common to take five UT measurements per meter, plus additional spot measurements. The Elios 3 provided clear visual data, making it easy to identify areas for extra scans. Over four flights, the pilot collected over 20 measurements per flight, covering the first few meters of the duct. This efficiency allowed the team to perform additional demonstration inspections on other assets, impressing the site managers who were used to slower, traditional methods.2. Silo Cones

Next, the Elios 3 was used to inspect the cones of limestone silos. These large steel structures were raised several meters off the ground, making access difficult. Traditionally, this would require scaffolding or elevated work platforms, which are time-consuming and costly. Instead, the Elios 3 completed the task quickly. With just one pilot, the drone could measure 25–30 points per silo in 1–2 flights. The results were stored digitally with geolocation, providing a clear record of measurement locations for future reference. Additionally, the drone was able to inspect small ducts in the building’s roof — previously difficult to access. Now, these areas could be inspected in minutes, offering insights that were previously unavailable.Transforming Inspection Processes with Drones

The Elios 3 UT demonstrated remarkable speed, safety, and accessibility during a single day at the cement plant. It reduced the need for lengthy planning, special permissions, and extended downtime, allowing for quick and safe data collection.

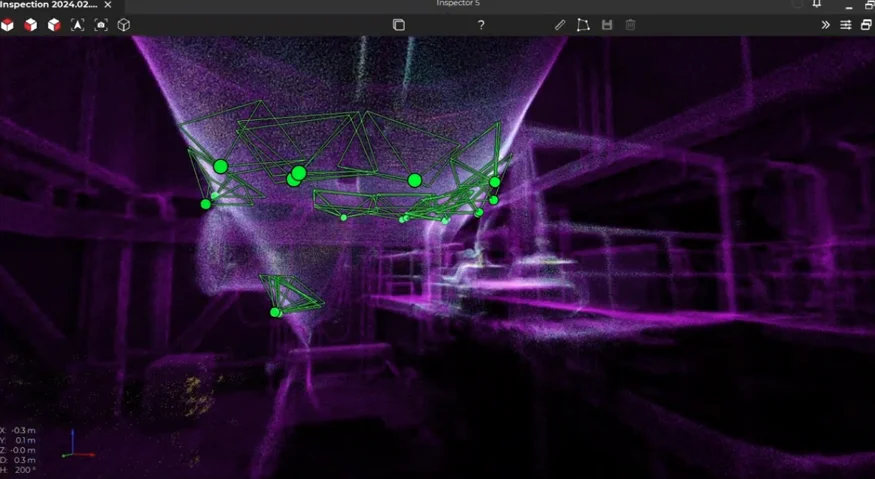

Quality of results: with the Elios 3 UT, it is easy to localize and record UT points ready for analysis later in Inspector 5

Beyond efficiency, the drone’s ability to access hard-to-reach areas improves the overall operation of the site. More frequent inspections become feasible, leading to proactive maintenance rather than reactive fixes. This not only saves costs in the long run but also enhances productivity without compromising safety. InspecDrone’s client was so impressed that they wanted to explore further applications of the Elios 3 UT for other parts of the plant. From flue ducts to silos and smaller duct systems, the drone proved that inspections don’t have to be slow or complicated — they can be fast, accurate, and reliable.Sports fitness equipment is often divided into two categories based on its training functions: single function and comprehensive multifunctional.

Single function equipment, commonly used include rowing machines, Exercise Bikes, walking machines, treadmills, waist machines, etc.

Comprehensive multifunctional device: generally includes the functions of chest press, assist dip chin, incline bench press, smith machine and other indoor sports equipment. Chest press, assist dip chin, and incline bench press are mainly used to exercise upper limb strength and pectoralis major muscle strength; Sit ups are mainly used to exercise the lumbar muscles and reduce excess fat in the waist and abdomen.

Laijian's complete service process:

1. Pre sales.

Establish user profiles, establish contact with customers, introduce our factory's technology and equipment, understand user needs, recommend corresponding fitness equipment, and provide quotations for the products required by customers.

2. On sale.

After completing the transaction, confirm with the customer the color, quantity, delivery time, and import information of the sports equipment products. Report the production progress to customers at any time during the production period to ensure their peace of mind.

3. After sales.

Responsible for the operation and maintenance skills training of personnel related to users.

Long term high-quality and cost-effective provision of spare parts.

The equipment has a shelf life of one year. If the strength training equipment is damaged due to its own quality within one year after acceptance, we are responsible for free maintenance.

import sports equipment,china sports equipment,training equipment for sports,indoor sports equipment

Foshan Laijian Fitness Equipment Co., Ltd. , https://www.ljfitnessquipment.com